Virtually all particle accelerators produce prompt showers of gamma rays, neutrons and other debris that arise from particles lost during accelerator operation; shielding is placed around operating accelerators to protect personnel outside. Concrete is the most-used shielding material for a number of reasons: it is cheap, durable and easy to manufacture, and can simultaneously act also as a structural building element in a facility; it naturally contains hydrogen atoms to shield neutrons and heavier elements to shield gamma rays; it does not activate as much as other materials (such as steel) so is easier to handle and dispose of; it can have a very long lifetime in excess of 50 years, enabling it to be re-used.

However, concrete has a significant downside – you typically need a lot of it; concrete shielding thicknesses are generally measured in metres. Concrete production also has a significant environmental impact: worldwide, concrete production contributes around 8% of all the world’s CO₂ output. Particle accelerator shielding and building concrete can give rise to as much as half of all a particle accelerator’s carbon emissions, for example in some of the planned future high-energy physics colliders even when electricity consumption over many years of operation is included. There is therefore a strong imperative to mitigate the carbon impact of using concrete.

As the UK’s hub for particle accelerator engineering, STFC is developing techniques to significantly reduce carbon emissions from concrete. We already routinely re-use building infrastructure and pre-cast blocks to offset emissions in new projects, and are pioneering the use of lower-carbon concrete in parallel with similar efforts more generally in the industry. One such example is the EPAC facility, which has utiliser Ground Granulated Blast Furnace (GGBS) material to reduce emissions by around half compared to using Ordinary Portland Cement (OPC). Within CESA, we intend to establish clear carbon accounting methods and guidelines for using/re-using modular low-carbon concrete and to test their use within projects funded by UKRI. This will be done in conjunction with updated shielding calculations being developed within STFC that have the scope to reduce the estimated concrete requirements for a given project.

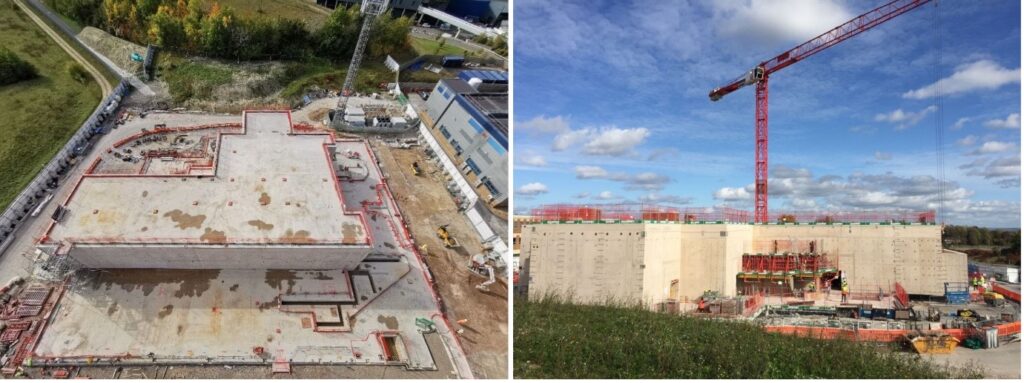

The STFC EPAC laser facility building under construction at our Rutherford Appleton Laboratory site. GGBS concrete usage has significantly reduced the CO₂ burden of constructing this facility, saving over 1300 tonnes of carbon emissions.